Good day,

I got a switch here that was able to turn on and be responsive, but the button input wasn’t working well. My cross directional buttons and the minus button didn’t respond, or the bumper L button.

I opened up the board and there was a lot of corrosion and indication for water damage. The daughter board was soaked, so I replaced it with another daughter board from a doner board. That went well. All buttons were responsive, except for one thing.

For some reason, when I pressed on any button, it would exit the button input test because it suspected that the button was being “held” down.

I looked around the forum for any related problems and there was one discussed about “ghost” input. Their solution was to reflow the CPU and the “ghost” input was gone.

I decided to do that first before deciding to switch the button input IC from the donor board.

Well now the switch doesn’t turn on…

Also, when trying to reflow the CPU, it.wouldn’t.budge…

I have my hot air gun for 460C at 55% air flow. I applied flux before the air flow and during the air flow, but it still wouldn’t budge when I try to push it slightly with tweezers.

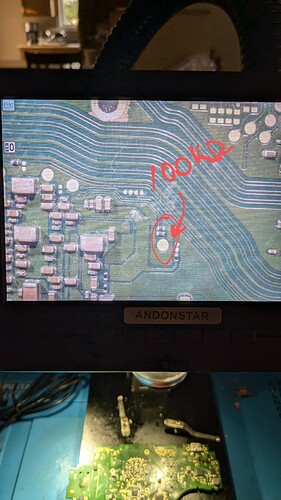

Now on the back of the board with the field of capacitors, one of the test points reads 100kohms, which on a good working board would be roughly 28kohms. So I know I did something or I bridged something somewhere.

But my main concern is the that the bga isn’t budging. Do any of you have any tips to slightly budge bga’s to reflow the solder? It’s like I’m applying heat on a stone.