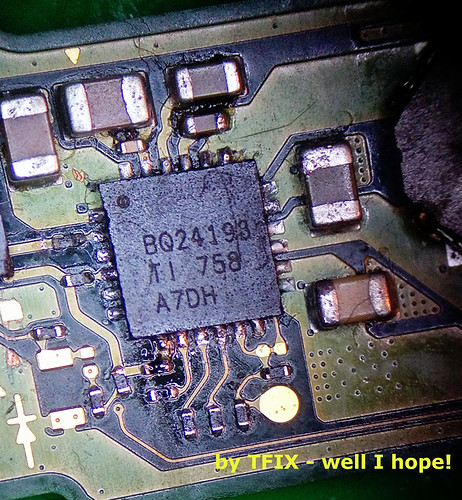

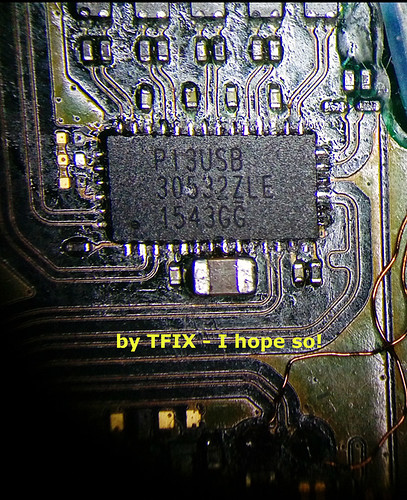

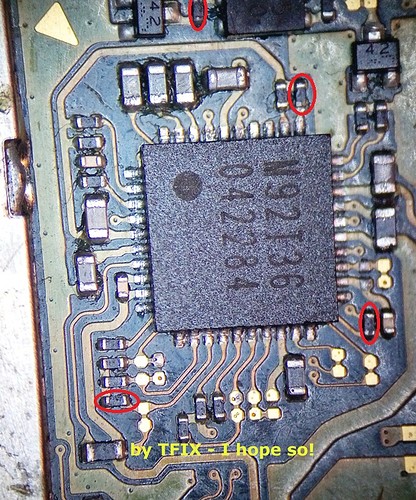

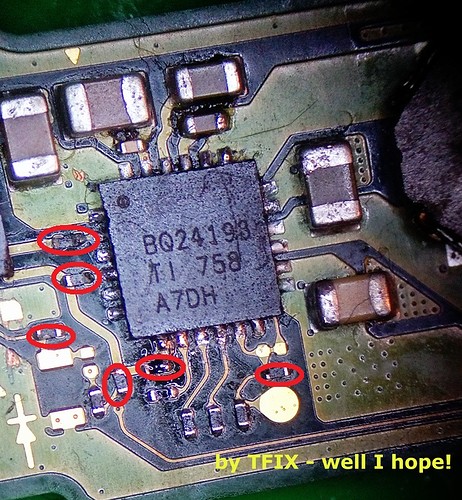

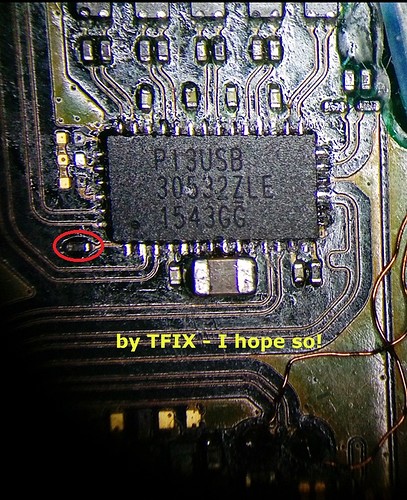

I will check those passives, but I am sure just maybe the one near PI3USB and maybe another - I think I did measure al lot of them - but of course they may misbehave when under load.

Most of the discolouration is probably the flux, which is not the best one (Kingbo) and I would have put it in a Sonic Bath - I have a cheap one for small PCBs and by holding it with my hand to avoid soaking the CPU!

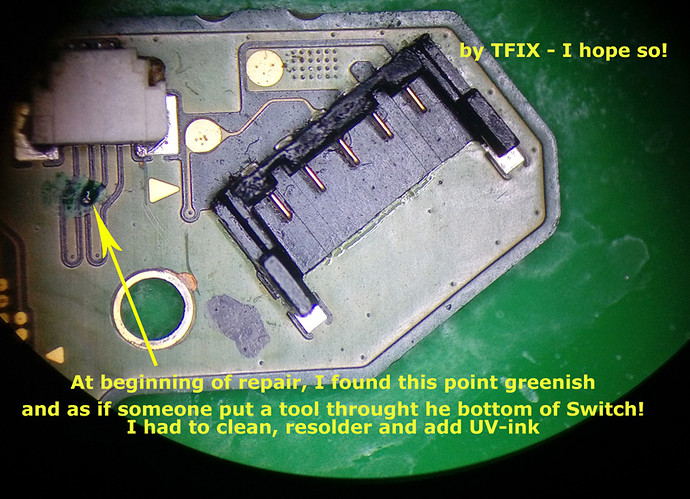

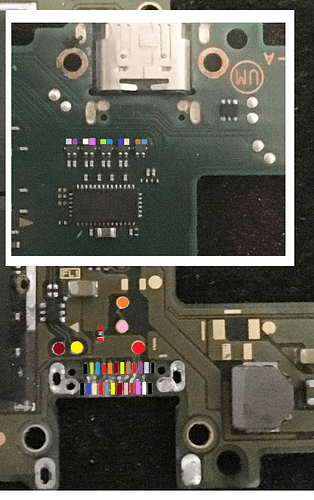

I already did a clean-up half way and I also did replace the port and re-wired it once and it was nicely done, as mentioned above, it looked a mess because I had to put my hand on it several times. It is all connected from external break-out board to end of wire on PCB - since I re-fit it never had a disconnection, but now looks like Hiroshima - as Northridgefix would say!

I would have done it again, although wiring is fine (!) and problem was only the ‘finally’ found correct connection of the underside pads and not the port itself, as second time I did use some UV-ink to lock the wiring and there was only one I had to join it externally as it snapped because I did not notice the wire had a ‘pre-cut’ on it.

Yes it is a mess now and the main reason it looks a mess, because it has become one, due to the incorrect wiring.

It always is the ‘first’ of my work - this one was for learning and I normally find ‘my way’ of doing things properly.

I used to work in telecommunications devices (mainly) on component level and done so many racks and the internal 10,000 wires in it, and the boss had chosen me because I was the one meticulous enough to be able to o a good and ‘safe’ job - always been, whatever I do. Especially when I worked as Technician for a Company doing harbour mathematical models - I loved that. Just treating the harbour in a few weeks, as if it had the sea battering it for 10 years!

I see how other do things I do not know, I learn and find a better and cleaner way of doing it - including my own drawings.

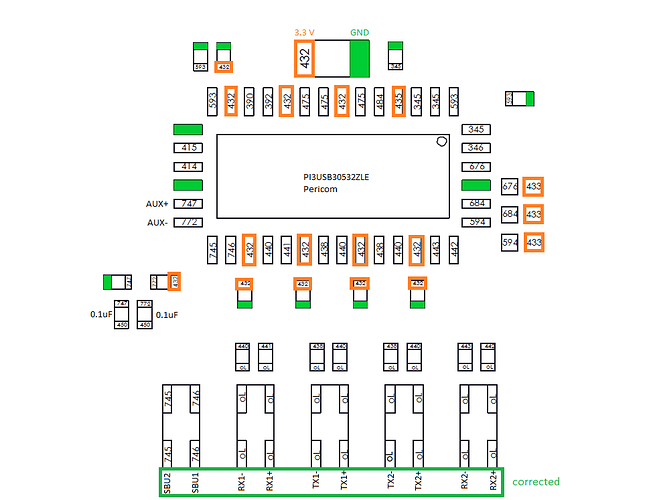

I applaud Calvin with the drawings as we probably think alike - in that sense - I do not like mess, but I am in a mess at present - I am even half way re-laying out my workshop - with main bench being micro-devices. One must do some drawings and measurement on a new device, which then will become second nature as with Calvin and Severence!

Now micro-technology I did not manage to get into about 10-12 years ago - for personal reason I could not do it - missed that boat.

Merry Christmas or not (if you are not bothered about it)… I am just following the herd these days … a little bit. Last 3 years had not a usual stupid Christmas.