Hello guy,

I bought this off ebay to see if I could fix it since I am bored in lock down

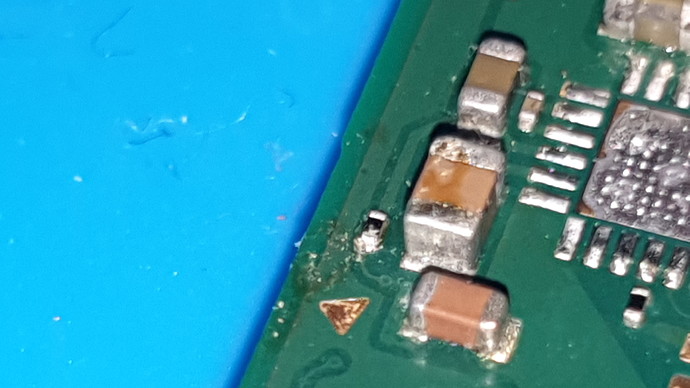

Anyway it was advertised as been broken and water damage.

Initially I was getting 38-41 AMPS after a bit of charging it would shot up to 1.14amp at times. So I was like great! But no screen or sound.

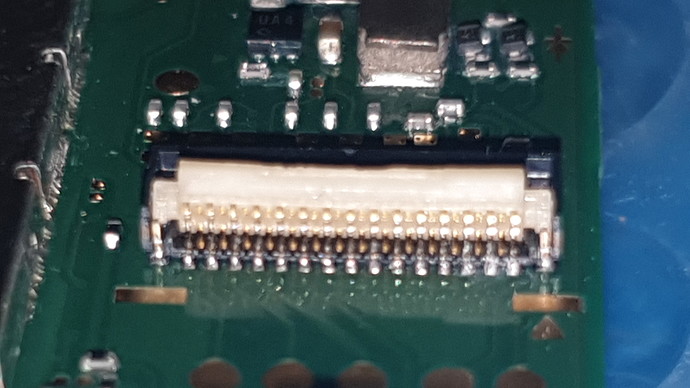

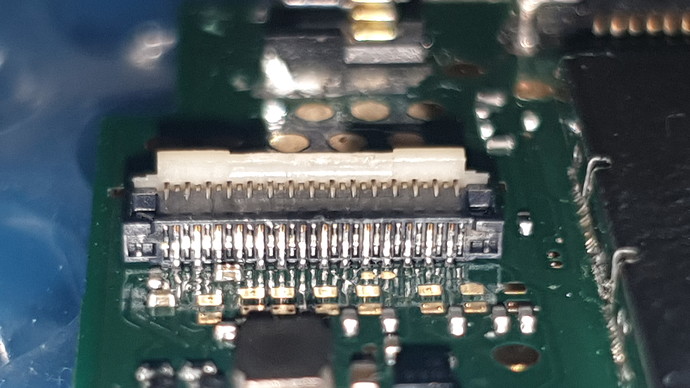

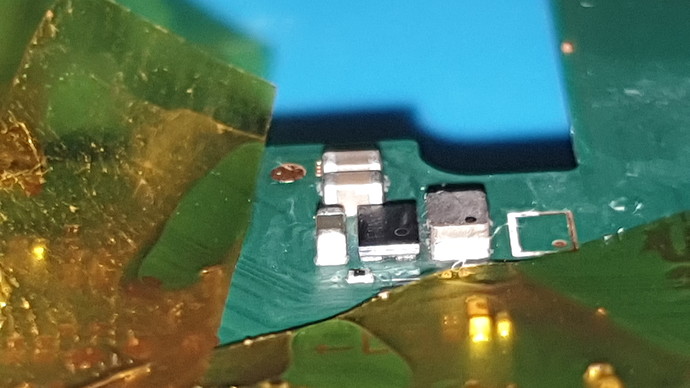

I could see on the screen it was stuck on boot loop when shining a light on screen. Took it apart and I saw corrosion on various ribbons and parts. Gave it a good cleaning with IPA. The backlight ribbon had a break in the trace, so I fixed that with solder and trip wire. Great, so backlight works! Now I see, Nintendo logo and Switch screen (and charging icon), but nothing further. It would either get stuck or go black (with back light).

I tried various chargers including official switch charger, didn’t much difference. Then I thought it could be the battery and tried a battery of another working switch lite in this switch lite. This is when things went wrong. Straight away got a blue screen. Switched it off and the blue light went away again and Nintendo logo came up again but no full boot. Tried again and blue light and came up again.

Current status :

Now I don’t seem to get anything on screen or back light (maybe I need to check the ribbon again). But I get a blue light on the home button only. It’s stuck on 38-41amps.

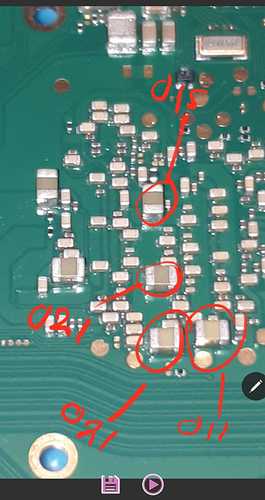

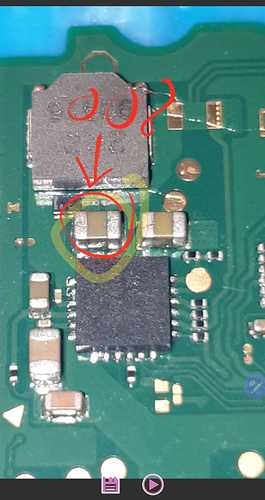

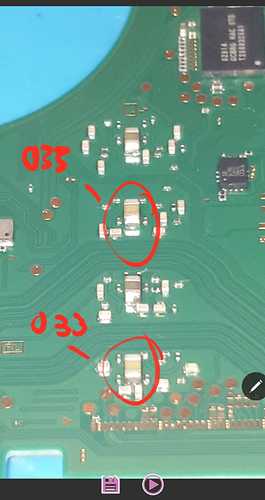

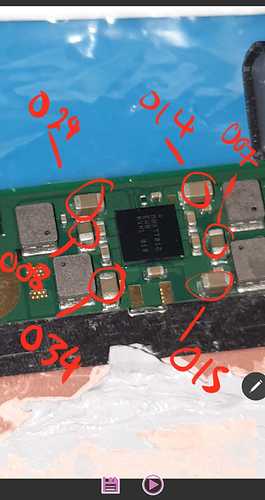

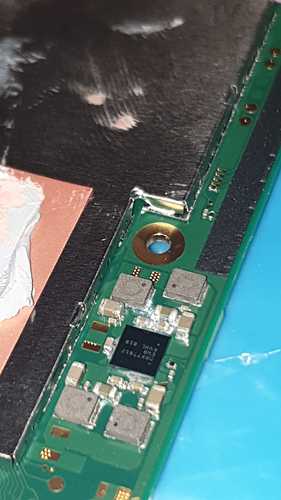

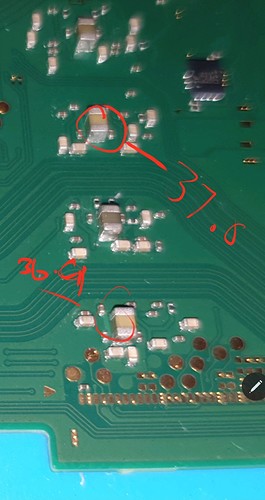

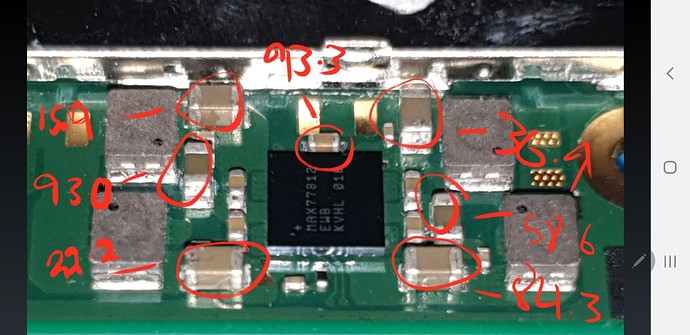

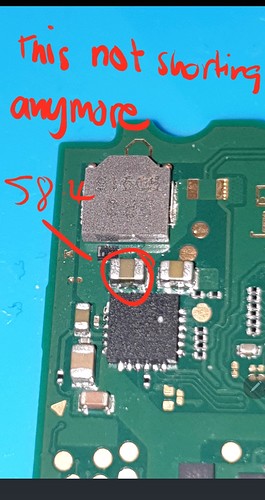

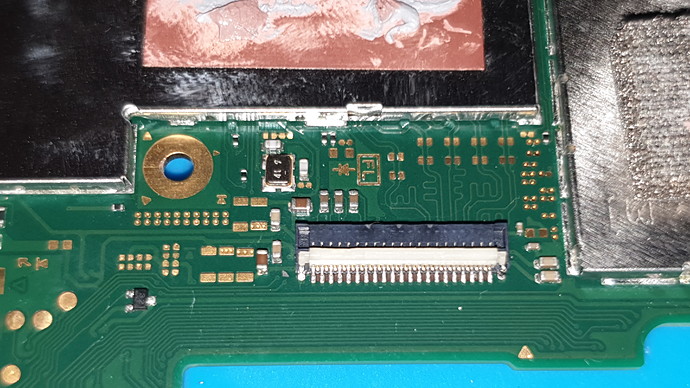

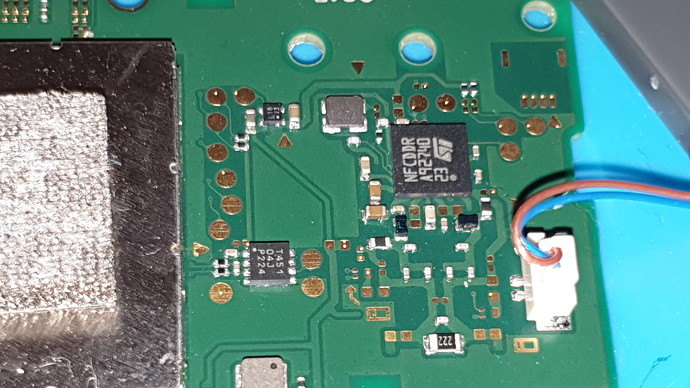

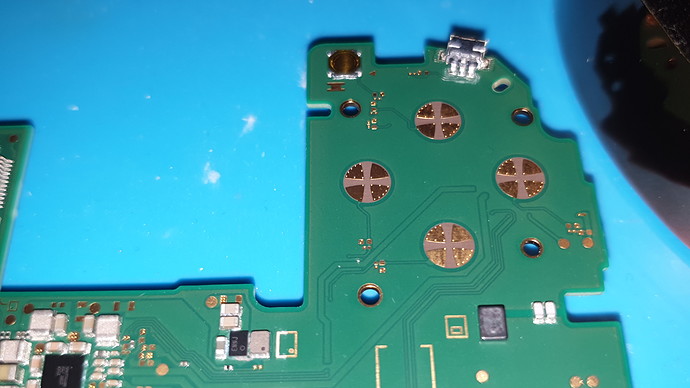

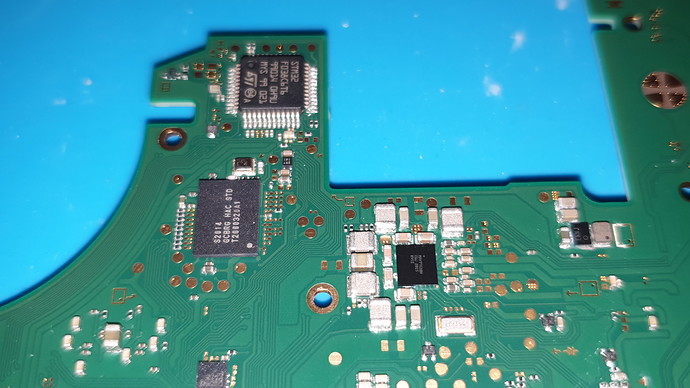

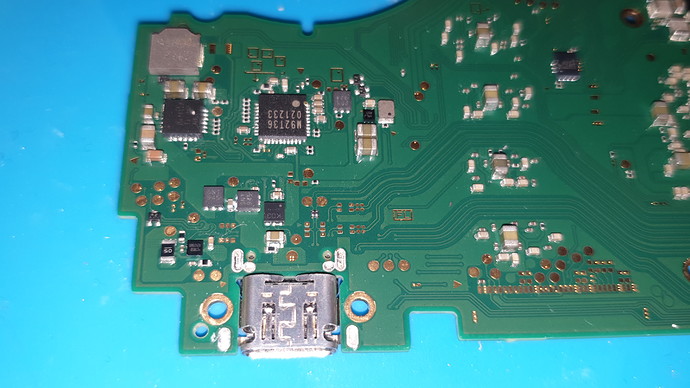

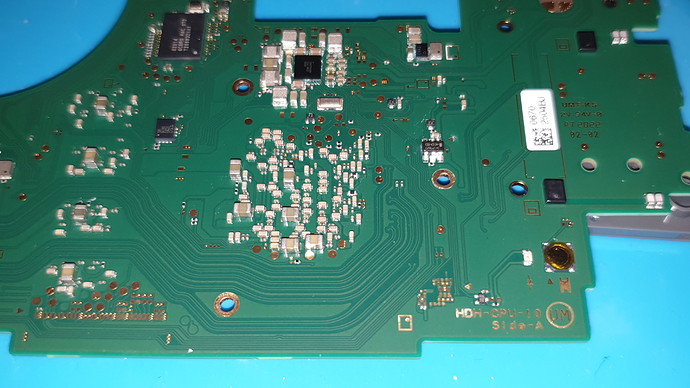

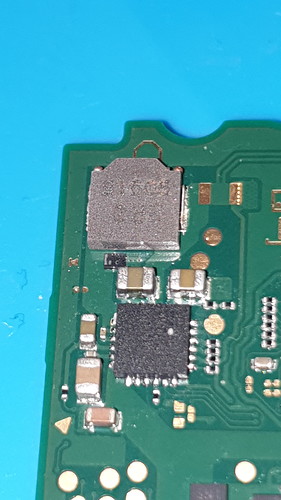

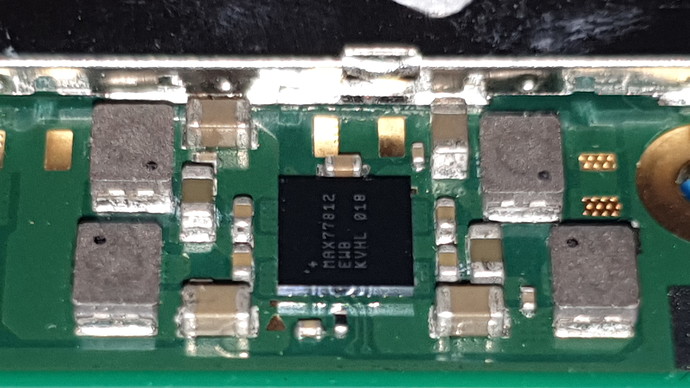

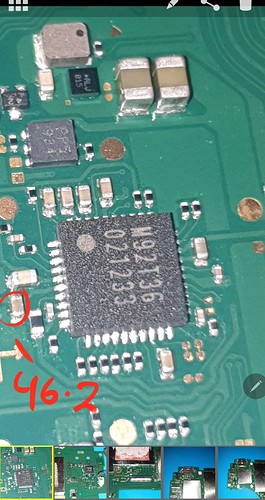

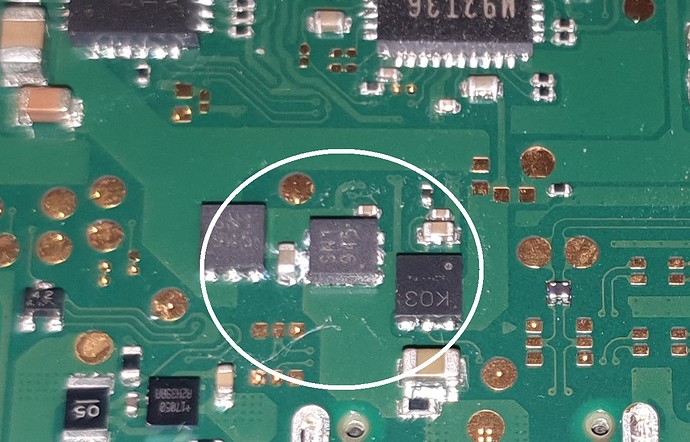

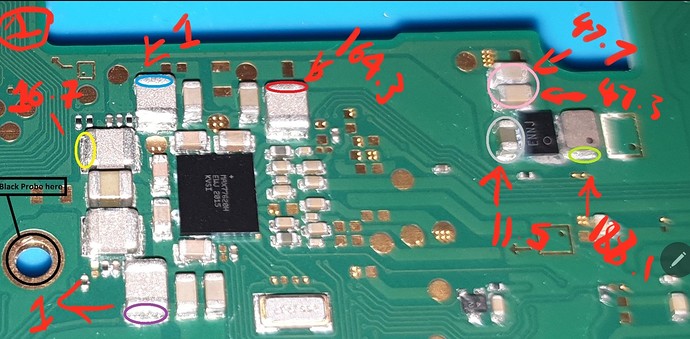

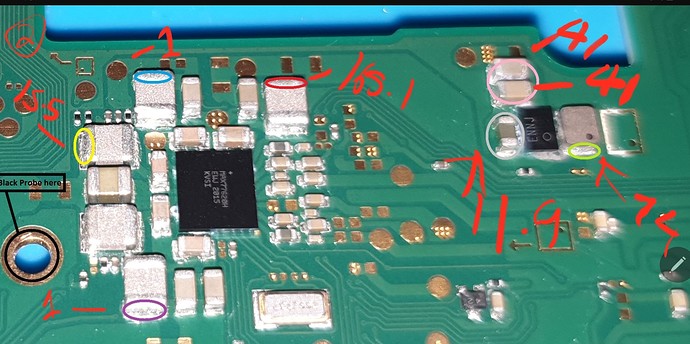

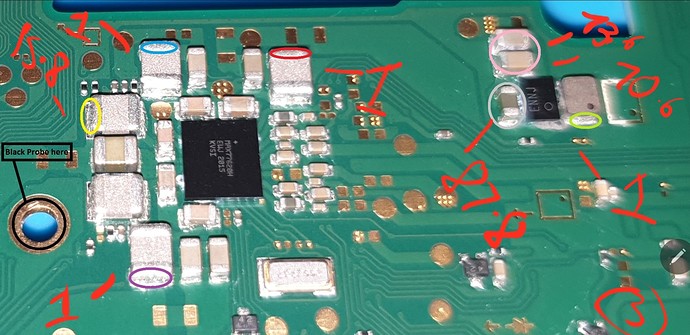

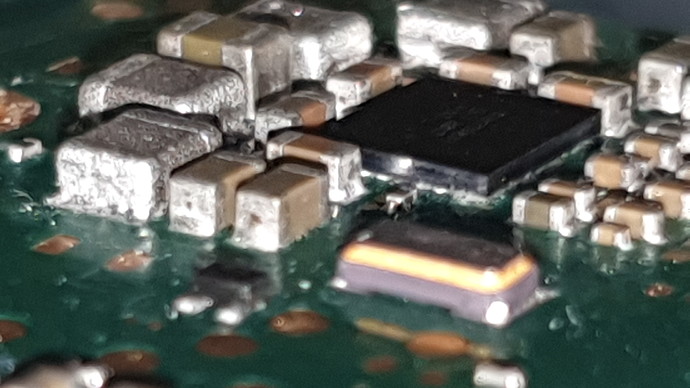

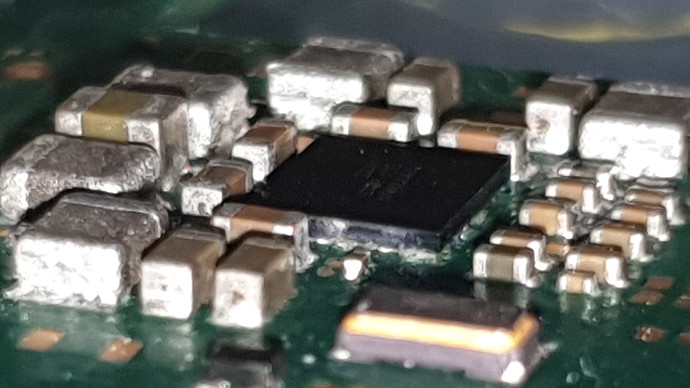

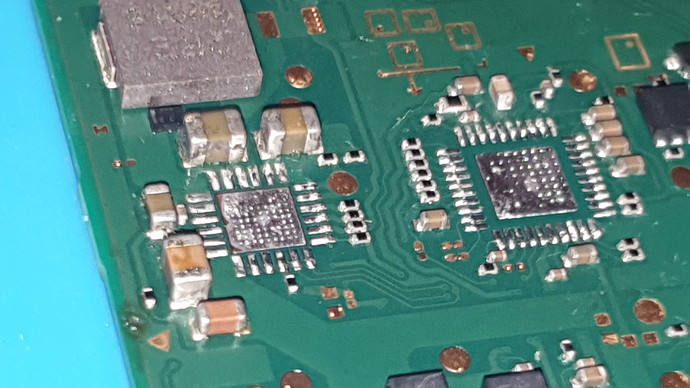

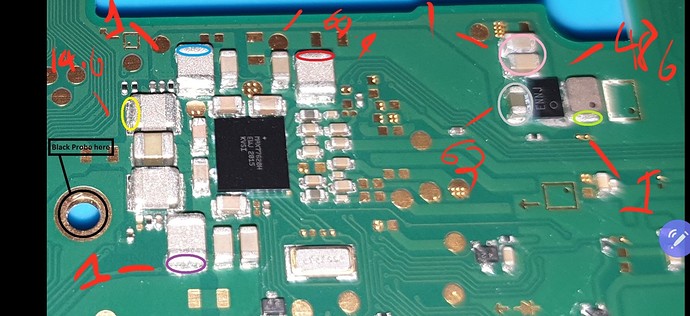

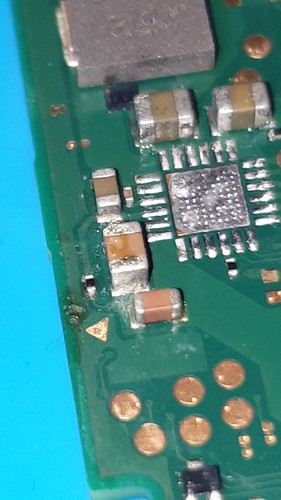

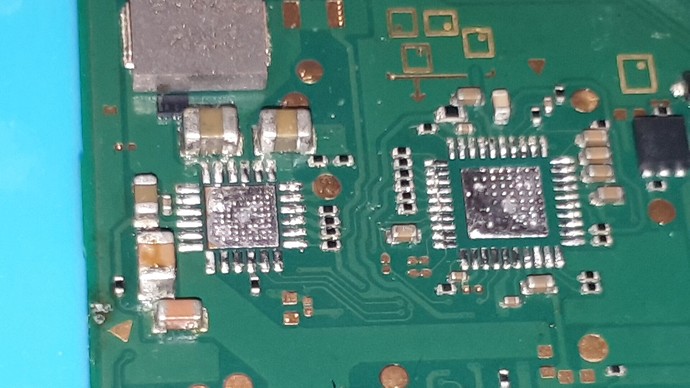

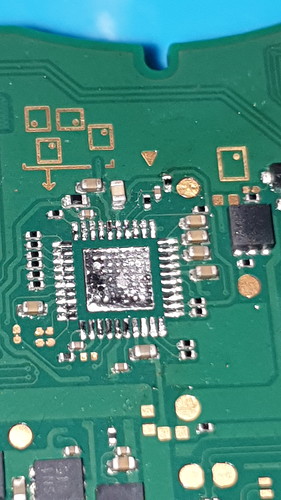

I checked for shorts and I have a few and took resistance measurements in the pictures, please see below.

Any advice on the next steps? I heard bluescreen of death is basically unrepairable but I figured might as well try something.