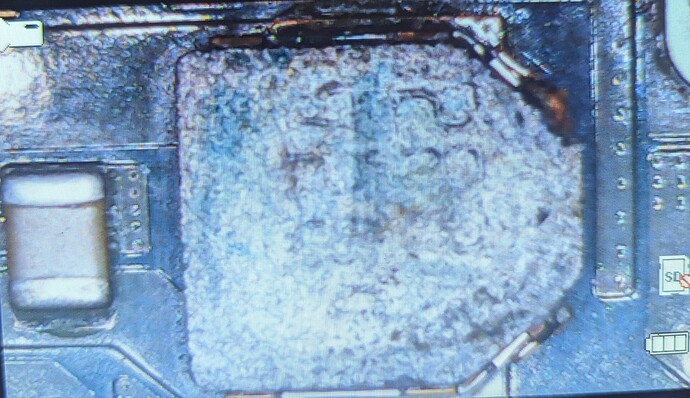

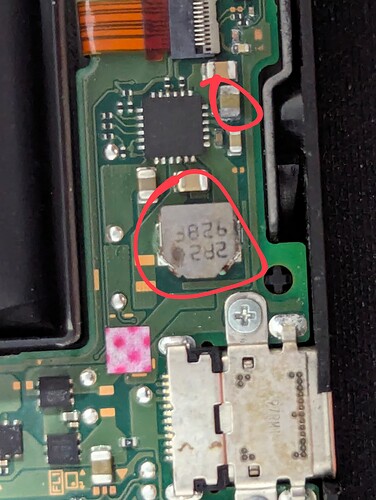

Looking at your image, your M92 IC is very clearly bad, you’ll wanna change it and make sure the dodgy looking pads below clean up nicely below following.

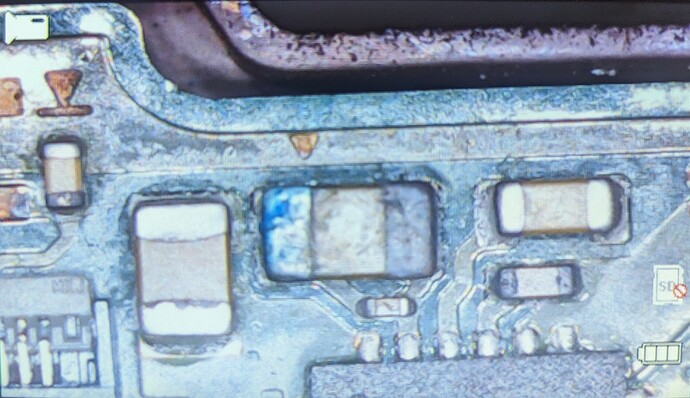

The capactors - You’ll wanna change out all the dodgy ones you’ve highlighted as a matter of course regardless of whether they test fine or not.

The 2R2 inductor, hard to tell from the image but it potentially has a bit of green on it indicating corosion, you’d also swap this out as a matter of course.

Most other people are checking for dead shorts when in continuity, depends of the meter but typically for measurments sub 50 ohms only.

I haven’t watched the video your referencing but if he’s measuring resistance across a bypass cap then he is measuring relative to ground, he’s presumably checking in resistance (which is the correct thing to do) as it may not be a dead short, if he was to have his meter in continuity and it isn’t a dead short then it would tell him absolutely nothing, if he was in diode mode and it’s not a dead short then he’d likely get a “good” reading, but if he’s in resistance then he’ll see it. (for example if it was a 500 ohm short to ground)

Not true, IPA can set off the liquid indicator, particularly IPA which has been hanging around for a while as IPA is hygroscopic, meaning, it will pull moisture, thus your 99.9% IPA is probably 96% after a while (as an example) meaning that 4% water is enough to set it off… I’ve even been able to turn them mildly pink with a fresh bottle of IPA, though they typically dry white again after a while.

Also, taking IPA out of the scenario, pink sticker does not definatively indicate liquid damage, they terribly unreliable, I’ve opened phones where the board is basically a rust and corrosion bucket and the sticker is still bright white and I’ve worked on counteless boards where the stickers have turned pink / red and there is no signs of liquid at all and they have obviously gone off as a result of humidity only.

That being said, in this case, the OP’s board is very clearly liquid damaged. despite the fact, as mentioned above the sticker didn’t change colour (until later)