Hi again. I would need your advice :). I ordered a cheap ultrasonic cleaner(without sweep function). Could you please let me know what kind of ultrasonic cleaner fluid are you using? How do you clean the board afterwards? Only putting into IPA bath or?

Thanks.

Hi again,

I don’t think my ultrasonic has a sweep function, though by the sound of it when it’s running the pitch is oscillating… so would guess it’s unintentionally frequency “sweeping” - i haven’t damaged any boards or components using it yet, so don’t think it’s an issue.

My unit is the same or like this one

Will say the QC on these is poor, and it originally arrived faulty, had a thermistor related hardware fault (which could have been dire if unchecked) and required repair… though this was a few years ago now, so maybe they QC has improved. Other than that the unit works well, despite claiming it’s 10L, you can only really get about 8L in it max, take this into consideration when adding your cleaning fluid (mix ratio)

Make sure to use either Deionized or distilled water as your liquid base. so approx 7L distilled/deionized water and approx 700ml of cleaning fluid (or whatever the mix ratio is)

Don’t whatever you do buy the fake board cleaning fluids that have flooded the market… if it’s bright blue, luminescent yellow or green, then it’s just glass cleaner/screenwash, using these will damage bare die IC’s.

The fluid i use is Chemtronics stuff, you can find it on mouser and it’s priced quite reasonable and lasts a long time.

I typically set the temp on mine to about 55C (and it will usually overshoot to about 60C in actuality) and i typically do four minutes per side with a scrub with a toothbrush inbetween (which there is no substitute for)

After Ultrasonic, I put the boards in a IPA bath for a few mins to displace any water and then put the board in an over at about 60/70C for atleast 30mins in order to get the boards bone dry, failure to thoroughly dry the boards can lead to board seperation during rework later so experiment with a scrap donor board to see how long it takes for your boards to dry and testing with hot air after etc.

Hope that helps

Many thanks for your detailed explanation.

This is what I bought

https://www.ebay.de/itm/3L-Profi-Ultraschallreinigungsgeraet-Ultraschallbad-Ultrasonic-Cleaner-Reiniger-/184591353759?_trksid=p2349624.m46890.l49292

It is only 3 liter but I do not really repair big things. For nintendo switch it should be fine.

I will order some original pcb ultrasonic cleaner. Or standard PCB cleaner should work the same?

After the IPA bath you dry the board and you told that check with hot air. Shall I than look for remaining stuff coming under the chips or also from the board layers itself?

An update for the shorted cpu switch. I ordered stencil and balls for the cpu reballing. Also a jig. And a direct heat stencil especially for switch. I hope they arrive soon.

Today with the Iphine stencils I reballed some of the ICs what I pulled off the board. It was really not easy but at the end I figured out a good tactic by fixing the stencil with 3 magnets than I do not have to hold everything with tweezers.

Thank you.

This is the stuff I use https://www.mouser.co.uk/ProductDetail/Chemtronics/ES132?qs=nqA2LZC%252BOeTagyjF30jyvA%3D%3D

If you can buy Branson EC in your country then you can use that instead.Can’t get it in the UK ![]()

I hope it works ok, the reason i got the 10L wasn’t really because of it’s capacity, which while handy for other board etc it was more down to the transducer count (which from memory is 4 or 6), the more transducers and in turn the more W equates to greater cleaning action… the concerning thing with the one you’ve selected is it only seems to have 1 transducer. I have a a jewelery style ultransonic with only 1 transducer and it’s pretty useless ![]() the other part which may be of concern is they claim the unit is only 100W but the heater is also somehow 100W… now what is the power of the transducer if this is the case (doesn’t make sense)… some of the cheap ultrasonics rely on the heat generated by the transducer/s instead of a dedicated heating element, and this may well be what they’re doing in the unit you’ve selected, heating is also crucial to the cleaning action - if it doesn’t get to temp in a timely manner then it’s not going to properly clean the boards. If they haven;t shipped it out yet, it might be worth considering cancelling the order and spending the extra approx 30EUR on the other.

the other part which may be of concern is they claim the unit is only 100W but the heater is also somehow 100W… now what is the power of the transducer if this is the case (doesn’t make sense)… some of the cheap ultrasonics rely on the heat generated by the transducer/s instead of a dedicated heating element, and this may well be what they’re doing in the unit you’ve selected, heating is also crucial to the cleaning action - if it doesn’t get to temp in a timely manner then it’s not going to properly clean the boards. If they haven;t shipped it out yet, it might be worth considering cancelling the order and spending the extra approx 30EUR on the other.

You’ll be able to tell when on a donor which after ultrasonic, bringing an IC up to reflow for removal and the board (and possibly components, depending) will noticeably bubble (layers seperating) if the board still has moisture between the layers… I’ve only encountered this less than a handful of times, and it’s typically down to the previous owner or tech over ultrasonically cleaning the board and/or severe liquid damage cases (submerged in a lake or bath for example)

I bought it based on a good review from a guy in UK (SDG Electronics Youtube channel) He opened it in the video.

It has 2 transducers (100W) and a separate heating element(Also 100W). So it should be good for this size.

Oh, might be fine then ![]()

I know this channel, and while i like him and his content, take his reviews with a pinch of salt… I took his advice on the cheap non standard amscope binocular microscope, received it, it was junk and promptly returned and i bought a real trinocular microscope with standard lenses.

I also like him. I bought also my microscope camera based on his review but this is already a newer one. It is a full HD 60FPS Eakins and it is really good. I use it with a monitor. It is not bino or trinocular because I hate watching through 2 holes for hours ![]() I get used to it really fast.

I get used to it really fast.

How many times are you reusing the same cleaner mix? Or how long do you store it in the ultrasonic cleaner?

tbh i haven’t changed the mix since the beginning… though i typically give my boards a minor scrub down with IPA prior and clean of any excess flux etc prior. I just leave the mix in the tank, as long as your using deionized/distilled water it’s fine and won’t rust the tank.

I suppose you’d change the fluid once the liguid is no longer see through, mines still fairly transparent, and still effective so see no need in changing it yet.

Hi again. I just wanted to give you some info. Today I received my Ultrasonic cleaner and also the cleaning fluid (EMAG-EM303 --> In Germany this was the only PCB flux cleaner I could buy…). The build quality of the cleaner is superb. I did not expected this. I made a 10% solution with distilled water and this EM303 flux cleaner, heated up to 60°C and put the board into it for 2x3 minutes. On the board there were on certain points 1-1,5mm thick 1 year old burned flux and the cleaner removed it 100% without any brushing. I was amazed. I did not expected this to be honest. I am really happy how it turned out. Afterwards as you recommended I put the board into an IPA bath for a few minutes while moving it back and forth on both sides a little bit. After that I put the board onto my 3D printer heated bed for 90°C for ca 40 minutes. Now the board looks like brand new.

Thank you for all the support.

Glad to hear everything all works well ![]()

I’m going to have to try this cleaning fluid out at some stage as i can imagine it being useful after repair of extreme liquid damge cases with severe corrosion, I can see why it would do a good job as it contains small amounts of sodium hydroxide (Acid: caustic soda) though it also seems to contain Ammonia… Icbw, but i seem to remember this was the reason why some people said glass cleaner would damage bare die IC’s as a result of this, if you can keep us updated on this later down the line if you have any problems in that regard.

That’s a great iidea, didn’t even think about using the printerbed for this, especially if you can kill two birds with one stone while preheating the printer.

Also forgot to mention - I’ve had no issues leaving the chemtronics fluid in the tank with no issues with rust etc, given the change in composition with your fluid your mileage may vary as a result of the acid/s so probably best to keep an eye on it after a week and drain it out and inspect the tank

I am not really affraid of corrrosion. I think they could not really sell this as PCB cleaner if it would cause chips to die. The concentration is really low with 10% solution. Plus the IPA bath is an additional gate to stop this.

Yes, I covered it with an alufoil to slightly insulate it but not fully to avoid humidity.

I do my repairs in our bed room because we live in a flat and no other option so I will empty my solution from the cleaner every time.

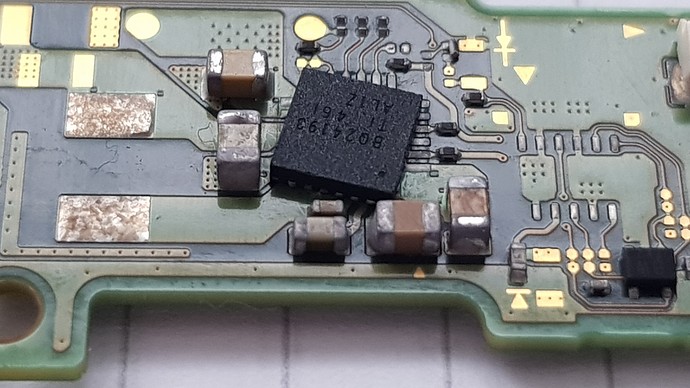

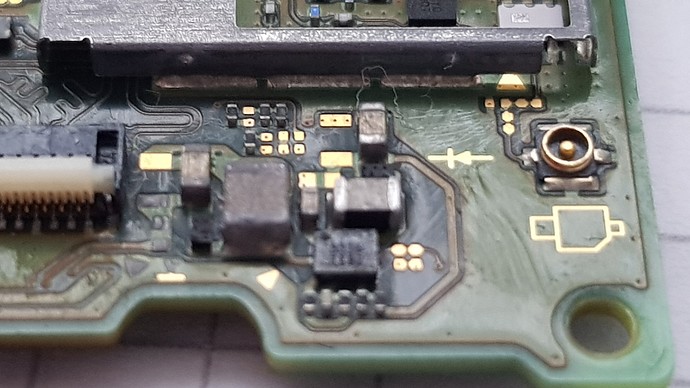

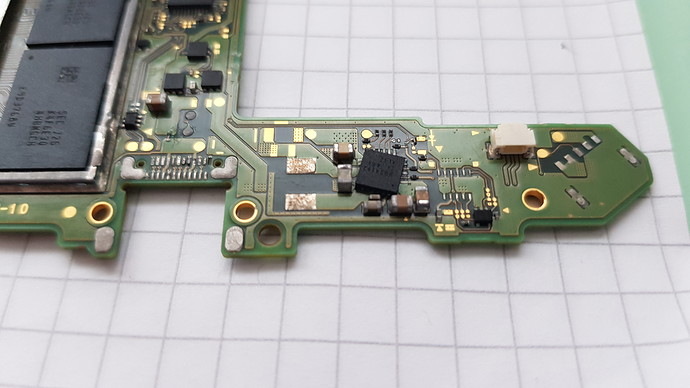

You migh have right with this liquid. Look at the pictures. Some pads and capacitors are discoloured lost their shininess…

I assume this is bad… :@

Interesting, i take it they were shiny prior? or did they etch/oxidize like this after the heat up on your printbed?

Was the WIFI shield frame quite so pitted prior to this also?

I suppose if this was caused after the heat up on the printbed it would imply there was still some of the solution present on the board and the heat accelerated the etching.

One thing i saw in the SDS

Removal of soldering masks,

which may just be a typo, or perhaps they’re reffering to a temporary mask… maybe someone more familiar with the PCB manufacturing process could chime in here. Though i think this is likely a typo, i see a few funny errors in the datasheet and SDS and think this is a language barrier issue.

If the parts above were shiny prior, then i think the easiest solution might by just to dilute it slightly more (?)

To be honest I have no idea but I think they were all shiny in advance. They look like etched now…

I suppose if this was caused after the heat up on the printbed it would imply there was still some of the solution present on the board and the heat accelerated the etching.

I thoroughly washed it in IPA bath for ca 10 min afterwards and than I put it on the printer bed… I do not know what to think.

I have some some new led boards now I will do some experiments with using the same liquid, afterwards with lower concentrationmand maybe also with and without heating. Lets see…

Will be interested to see the results.

If you have any nickel/tin plated steel shields from old iPhones or something then toss them in the pot too and see what the solution does to the plating and/or if it pits the metal.

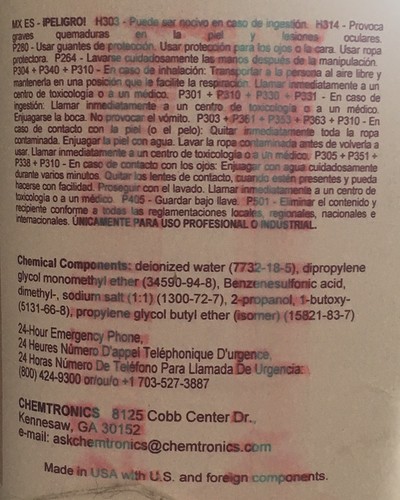

It’s a shame the Chemtronics SDS isn’t quite as clear as the EMAG one in terms of it’s ingredients… if it was, you could just mix up you own homebrew version of the chemtronics stuff  I’ll take a photo of the label on the bottle which may be a bit clearer

I’ll take a photo of the label on the bottle which may be a bit clearer

If you have any nickel/tin plated steel shields from old iPhones or something then toss them in the pot too and see what the solution does to the plating and/or if it pits the meta

Good idea. I will also put the switch wifi shield into it. I will do this experiment in the evening.

The DOE looks the following:

2pcs in the same solution. 1 dried one not

2pcs with half the concentration. 1 dried one not.

I will do before after pictures from all.

I will do before after pictures from all.

Cool ![]()

Here is a snap of the label on the Chemtronics fluid if your interested which is slightly clearer compared to the SDS, sorry the drips smeared the ink.

Thanks for the picture. I wanted to order this as you recommended, but it was only available in Mouser and they wanted to charge 20€ for shipping and additional 8€ for some kind of handling… This Emag was the only one I could find in Germany…

Just saw a video of Paul Daniels recommending this cleaner.

https://cpc.farnell.com/ambersil/6330001300/ultrasonic-cleaning-liquid-1ltr/dp/SA02601

Ingredients seem pretty similar to the chemtronics one, and hopefully it will be availiable in your country, it’s on farnell which operates worldwide so maybe…

Might be an option depending on your tests.