Nice Job

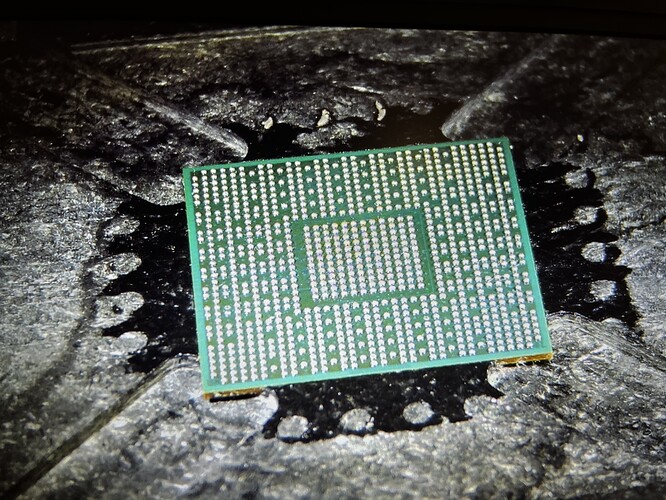

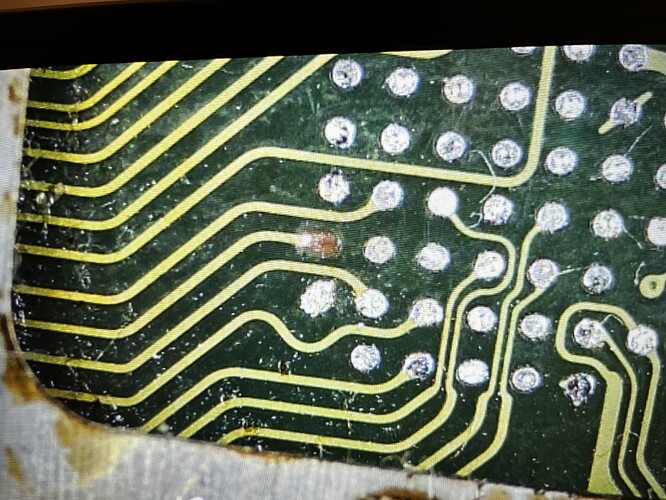

Just check the balls are a consistent height to one another, it’s near impossible for me to tell from your picture. For example, if you have even one ball which, let’s say, is 20% smaller than the rest, then that will likely not take to the board come reflow time, whereas on a smaller IC you’d probably get away with this, simply because the area is smaller. Also just to mention, using stencil and paste on packages of such a large size aren’t nearly as forgiving in general when compared preformed solder balls not least for the reasons I mentioned above but also because solder paste will always result in smaller balls when compared to factory/preformed balls, this is simply due to the flux content in the paste and/order hole size in the stencil… theoretically the stencil manufacturer could compensate for this by altering the hole size in the stencil… but they never do. What I’m getting at here, is, if your board has any amount of warp/bend etc preformed balls will help you out in this instance (I mention all this as it’s connected to what I’m going to say next  )

)

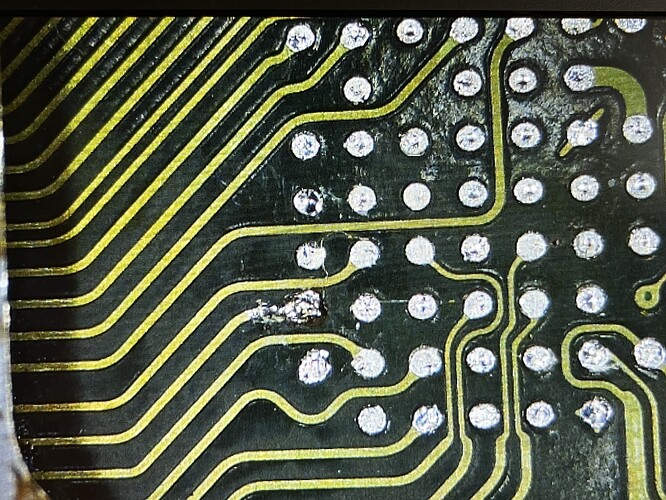

This is a little hard to tell if this was existing or caused by you during removal or wicking, but, those pads/lines going off to ram and this failure mode is typical on boards where the chassis has a bend (however slight) and the worst of the bend typically happens to the left of the USB area, ram and this edge of the SoC. I’ll often see those pads disconnect from the trace or, for the pads and the traces to pop up completely (incl the ones ram side) , I’ve even seen the whole row come up with the SoC during removal… I have repaired them in a few cases, though I tend to avoid it if I can and instead transfer the SoC over to another board. I’ve also noticed this issue on boards where people have replacesd the USB port… and I guess have mirrored the moronic YTer who basically mashes the USB port down come reflow and looks like he puts his whole body weight behind it  , which basically induces a bend like above, and then the board gets screwed back in to it’s flat chassis and the pads/joints/traces shear off or they fail over time.

, which basically induces a bend like above, and then the board gets screwed back in to it’s flat chassis and the pads/joints/traces shear off or they fail over time.

Hard to tell from your image but you’ll want to use UV mask on edge if you haven’t done already to help hold that pad down otherwise it’ll just get sucked up come reflow. You’ll also wanna check the other pads at least on that row too, poke at them and see if any feel spongy, scratch back the mask on the corresponding traces and check continuity etc as sometimes in the cases I mentioned above, there will be a break which is near impossible to see, typically at the pad itself. Depending on the outcome, you may find some of the pads at ram will have the same issue too, so worth keeping that in mind.

Trouble in cases like this is, you may go to all the effort to find and fix the damage, but there may be trace damage on the internal layers too, so even if the repair is successful and everything works great following, problems could still occur later on which is why I do try avoid reusing boards in these cases, particualrly if I’m doing the repair for someone else or intend on selling the device… thought it worth mentioning